Clinker Replacement Is Most Viable To Reduce Cement’s Greenhouse Gas Emissions

Clinker Replacement Is Most Viable To Reduce Cement’s Greenhouse Gas Emissions

Everyone is aware that cement plays a critical role in shaping the country’s future as the propeller of growth. As the foundation for a firm footing, it is not just central to the local economy but crucial to the global economy, especially in finance, where global in-vestment holds the key. However, the cement industry is also one of the most energy-intensive and significant greenhouse gas emitter. It is pertinent that the sector’s future growth must not come at the cost of environmental degradation.

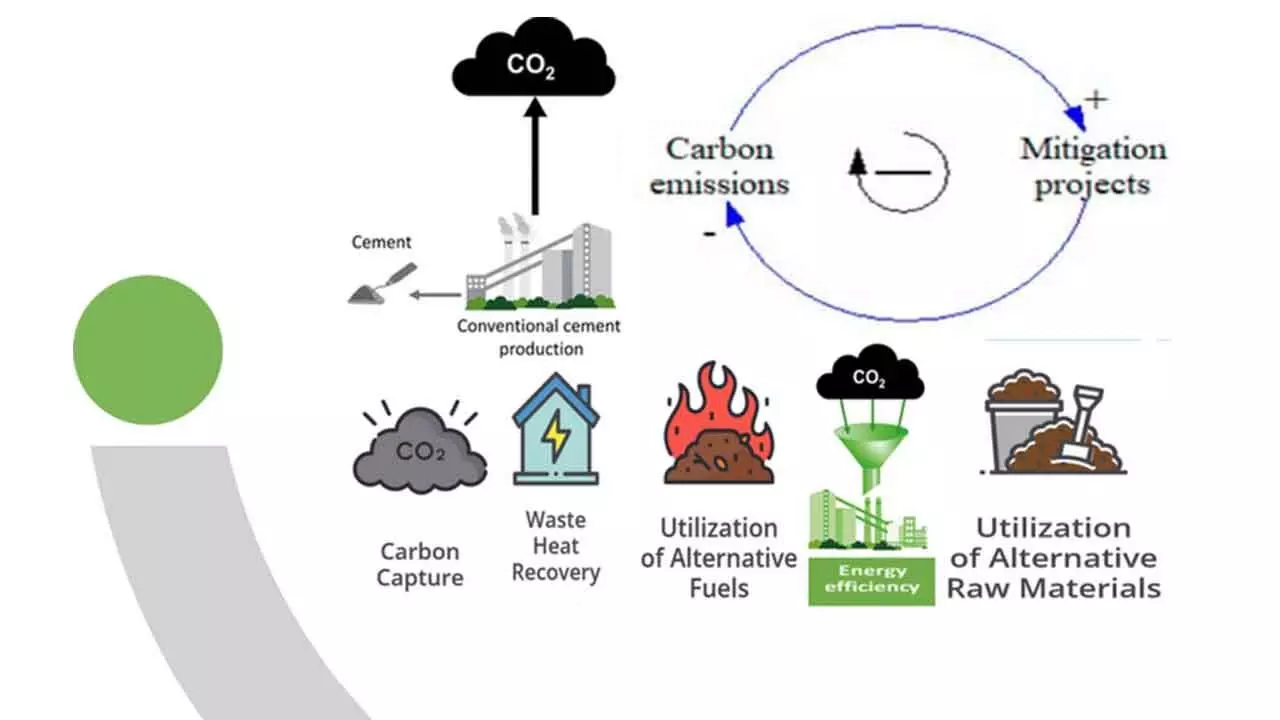

Global warming is an undeniable reality and cement is one of the largest contributors to CO₂ emissions. The global cement production is projected to increase from the present four billion tons annually to five billion tonne over the next 30 years. Thus it is imperative that reducing emissions will become the key driver for the industry’s sustainability. Among the four strategies—thermal energy efficiency, fuel replacement, carbon capture, utilisation and storage (CCUS), and reducing the clinker-to-cement ratio—clinker replacement emerg-es as the most effective short-term solution.

It brings along numerous advantages: it is easy to implement, doesn’t require new equipment or fuel changes and delivers measurable and impactful results, while signifi-cantly lowering direct emissions. The cement industry has a pivotal role in combating climate change, and clinker replacement stands out as the most practical, cost-effective step we can take today. Interestingly, producing clinker requires 1450°C of heat, in-volving substantial energy consumption. Mining, transportation and other activities also heavily rely on diesel, adding to carbon emissions. The government still specifies the use of OPC cement instead of PPC, despite the latter being more sustainable. Small recycling units must be established, and individuals, industries and the government must work together to reduce pollution.

The challenge lies in reducing carbon foot-prints, which makes digitalisation and technological innovation imperative for organi-sational growth. Adopting the latest digital technologies requires significant invest-ment, technical expertise and, most importantly, a cultural shift within organisations. Digital transformation demands a transformed mindset, bridging skill gaps and growth-centric training. Resource allocation is a key factor as digital initiatives require strategic investments.

One must not forget that cement production accounts for seven to eight per cent of global greenhouse gas emissions, making it a sector under constant scrutiny. In India, per capita cement consumption stands at approximately 250 kg, compared to the glob-al average of 500 kg. With infrastructure being a cornerstone of economic growth, In-dia's cement consumption is poised for sustained growth over the next decade. We now have cement plants capable of operating solely on waste recovery, which is a significant milestone. However, challenges persist in securing a reliable supply chain and ensuring material availability.

Technological innovation within organisations is crucial to ad-dress these issues. While the cement production process inherently emits CO2, captur-ing it in a commercially viable way is essential. One approach is reducing nitrogen to achieve a dense CO2 concentration, enabling efficient capture. Additionally, cement in-dustry has the potential to produce green hydrogen, a key component for decarbonisa-tion. Green cement with zero CO2 emissions is achievable but it requires robust poli-cies, an enabling environment and customers willing to pay a premium for sustainable solution. This initiative must be pursued seriously to achieve net-zero emissions in cement industry well before 2050.