How India Is Preparing For The Future Of Manufacturing

Indian govt is actively promoting manufacturing growth through various initiatives, including significant budget allocations for infra development and employment-linked incentives

How India Is Preparing For The Future Of Manufacturing

These efforts aim to create over 6 million jobs in the sector in FY25-26. Key drivers include government initiatives like PLI schemes, increased domestic demand, and advancements in Industry 4.0 technologies

The government has discussed several policies and incentives to boost manufacturing jobs in the FY25 budget, focusing on employment generation and industrial growth. In Union Budget the govt. has allocated Rs 11.11 lakh crore to upgrading and expanding industrial infrastructure. This would account for 3.4 per cent of the GDP, crucial for developing the manufacturing sector. There are some key initiatives for boosting employment in manufacturing.

Employment Linked Incentive (ELI) Schemes like

This scheme targets individuals entering the workforce for the first time. The government provides a one-month wage to these new employees, disbursed in three installments, with a maximum benefit of Rs 15,000.

Similarly, job creation in manufacturing scheme offers incentives to both employees and employers based on their EPFO contributions over the first four years of employment. It aims to benefit around 30 lakh young entrants.

Besides, support to employers, scheme focuses on encouraging additional employment by reimbursing employers up to Rs 3,000 per month for two years towards the EPFO contributions for each additional employee hired.

Around 1,000 Industrial Training Institutes (ITIs) will be upgraded to hub-and-spoke arrangements under with an outcome orientation under Skilling Program. This would help create more skilled employees in the industrial sector and eventually equip manufacturing industry 4.0.

Talking to Bizz Buzz, Subburathinam P, Chief Strategy Officer, TeamLease said, “In the fiscal year 2025-26, the Indian manufacturing sector is projected to create more than 6 million jobs. This growth is driven by various government initiatives, increased domestic demand, and companies expanding their capacities. The government's focus on production-linked incentive (PLI) schemes and infrastructure development has significantly contributed to this positive outlook.”

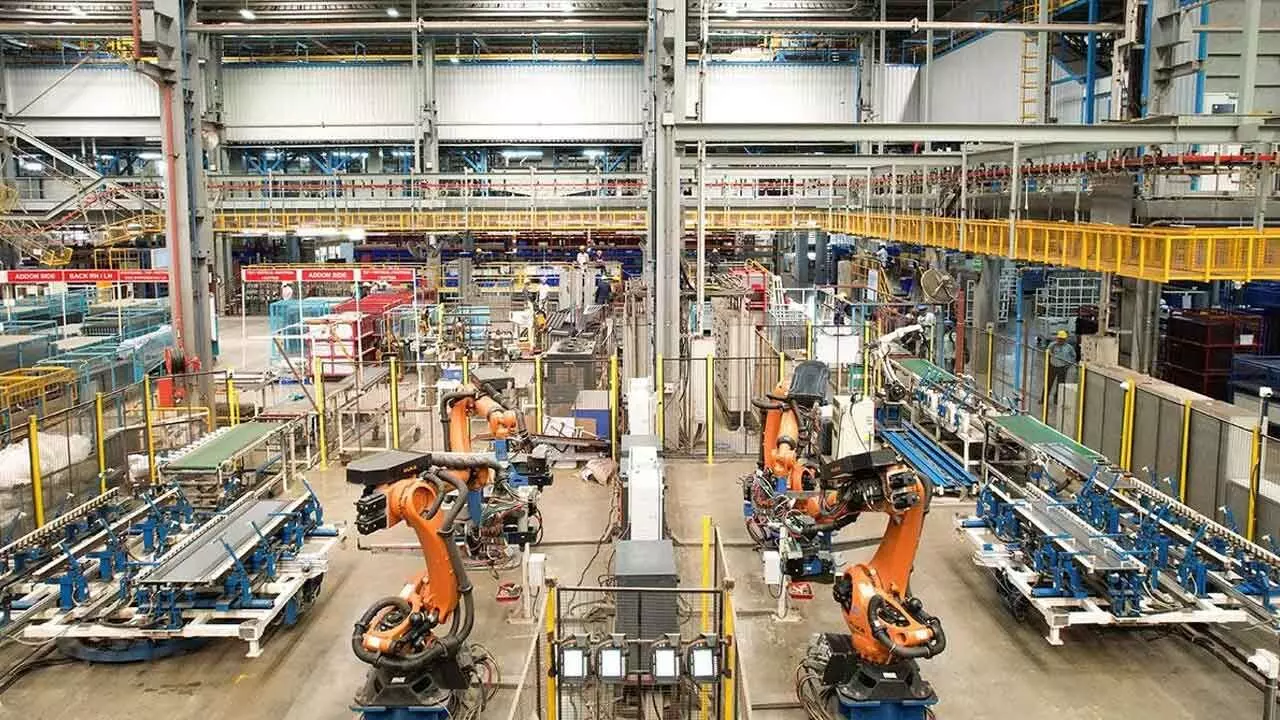

In the past five years, India's manufacturing industry has seen significant growth fueled by several key factors. Government initiatives, advancements in industry 4.0 technologies —including automation, artificial intelligence, and the Internet of Things (IoT) — and a boost in foreign direct investment (FDI), which totaled $383.5 billion have all contributed to this progress.

Among blue-collar, assembly line workers, logistics personnel, welders, fabricators, CNC operators, machine operators are most in demand.

Coming on white-collar, production supervisors, quality control inspectors, Supply chain managers, and industrial engineers, technicians, sales executives/consultants, and service engineers are most in demand.

The PLI scheme, introduced in 2020, offers financial incentives to companies for incremental sales of products manufactured in India. This initiative has attracted over $17 billion in investments across 14 sectors, including electronics, pharmaceuticals, and textiles, resulting in production worth approximately Rs 11 trillion and the creation of nearly one million jobs over four years.

The Make in India initiative, launched in 2014, aims to transform India into a global manufacturing hub by encouraging both domestic and foreign companies to manufacture in India. This program has led to increased foreign direct investment and the establishment of numerous manufacturing units across the country.

Additionally, the government has launched several apprenticeship programs, such as the National Apprenticeship Promotion Scheme (NAPS) and the National Apprenticeship Training Scheme (NATS). These programs aim to provide youth with practical training and industry exposure, enhancing their employability in the manufacturing sector. By fostering skill development, these initiatives directly fill the skilled labour gap and prepare a workforce suited to the evolving industrial needs.

According to the Annual Survey of Industries (ASI), employment in India’s manufacturing sector dipped slightly in 2020-21 due to the pandemic but rebounded with a 7 per cent year-on-year growth in 2021-22.

In October 2024, India's business activity marginally accelerated, driven by robust demand in the manufacturing sector. The manufacturing Purchasing Managers' Index (PMI) increased to 57.4, indicating expansion and the fastest job creation rate since February 2006.

Surinder Bhagat, CEO & Founder, Gigin AI said, “Given the current growth trajectory and government support, the manufacturing sector is poised for continued expansion, assuming a conservative annual growth rate of 10-15 per cent in FY25 and an additional 1.2 to 1.3 million jobs in FY26.”

Gigin’s platform highlights the rise of digital and automated roles within the sector. Positions related to automation operation and digital quality assurance are expected to grow in demand as manufacturers adopt smarter, more efficient technologies, he added.

Technology continues to reshape the manufacturing sector, with automation and digital tools driving significant changes. Skills in automation, robotics, and digital manufacturing technologies are becoming increasingly valuable. This technological shift is expected to create new opportunities in the sector, particularly in roles related to machine learning, AI-based quality checks, and digital process management.

Gigin's platform is already seeing a rise in job postings for roles that require expertise in automation, indicating that businesses are preparing for this new phase of industrial growth.