Rising patronage for 3D printing leading to manufacturing renaissance

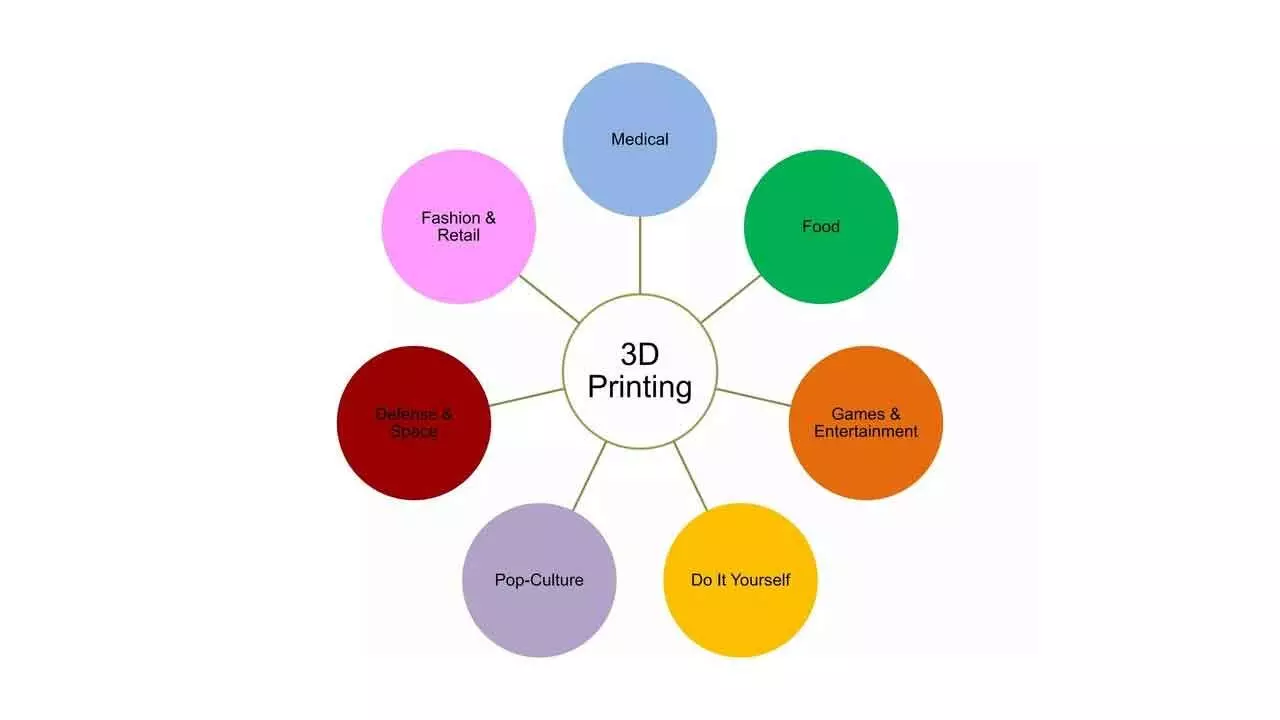

3D printing is one of the promising technologies with the potential to transform mainstream manufacturing

The driving factors of the 3D printing market are the aggressive R&D in three-dimensional printing as well as the increasing demand for prototyping tools from numerous sectors, particularly automotive, healthcare, aerospace and defence

3D printing is a type of industrial robotics. Sometimes referred to as additive manufacturing, it refers to the use of a computer to produce three-dimensional products of many shapes and forms. Well developed in the United States, Europe and Asia, this new technology is now penetrating Africa.

The ability to print complex parts is “one of the most disruptive innovations I’ve seen in the manufacturing space in my 37 years here. Manufacturing is going through a renaissance,” says David Joyce, CEO of GE Aviation.

The global 3D printing market size was $ 20.68 billion in 2023, accounted for $ 24.61 billion in 2024 and is expected to skyrocket to around $ 117.78 billion by 2033, expanding at a CAGR of 19 per cent from 2024 to 2033.

General Electric Co. shook up the 3D printer market last year by laying down more than $one billion on two acquisitions. Eventually, that has turned out to be just the beginning.

3D printing is one of the promising technologies that have the potential to transform mainstream manufacturing. It provides flexibility in the manufacturing of complex geometries at competitive prices and within a low production time. 3D printing is fast gaining traction among various industries. The burgeoning adoption of industrial revolution 4.0 is a major factor that is boosting the 3D printing market growth. Competitive pressure and ever-evolving business model are compelling companies to shrink development cycles and move in the right direction with speed and agility.

As a result, 3D printing is transforming manufacturing and providing flexibility, customization, time-to-market, distributed manufacturing and much more.

In 2023, the industrial printer section is expected to account for more than 77 per cent of total revenues. The common use of industrial printers in industries such as electronics, automotive, defense and aerospace, and healthcare is attributed to the large part of industrial 3-D printers. A few of the prevalent industrial applications in these industries are prototyping, design and tooling.

The widespread use of 3-D printing for prototyping, design, and tooling is promoting rising industrial demand. As a result, the industrial printer segment is predicted to maintain its dominance throughout the projected period.

The burgeoning technology is becoming a new product line as well as a central component of GE’s effort to modernise its manufacturing operations, boost productivity and reshape how everything from locomotives to medical scanners to jet engines are made.

The market is distributed into two verticals: desktop 3D printing and industrial 3D printing. Automotive, healthcare, aerospace and defense, consumer electronics, energy and industry, power, and other verticals are being regarded as industrial 3D printers. In 2023, the automotive sector held the largest market, accounting for more than 25 per cent of total revenue.

Last year, the metal sector had driven the 3D printing market and it is estimated to account for approximately 53 per cent of global revenue. Stainless steel powdered for the sintering/melting/EBM procedures is among the strongest and hence the most frequently used metal for 3D printing.

The polymer sector was the fastest-growing segment. Polymer 3D printing is expected to generate $11.7 billion in revenue in 2023, which includes hardware, materials and 3D-printed parts sales.

The medical field was an early adopter of polymer 3D printing. Currently, the technique has a variety of applications in the medical field, ranging from 3D-printed surgical tips and tools to human tissue replacement for pre-surgical preparation. Polymer 3D printing has proven to be a practical technology for producing safety goggles, ventilator valves, face-shields as well as testing swabs since the start of the Covid-19 pandemic.

During the forecast period, the software sector is expected to grow at a rapid CAGR. 3D printing software is often used to develop products as well as parts that will be printed in a wide range of business verticals.

The driving factors of the 3D printing market are the aggressive R&D in three-dimensional printing as well as the increasing demand for prototyping tools from numerous sectors, particularly automotive, healthcare, aerospace and defence.

There were approximately 8.71 lakh 3D printing machines in use in 2021 and 2.2 million 3D printers were supplied to clients globally; between one and two million people use 3D printers worldwide.

The major players operating in the 3D printing market are Stratasys Ltd., EnvisionTec, Inc., Materialise, 3D Systems, Inc., Autodesk Inc., GE Additive, Voxeljet AG, Made In Space and Canon Inc., among others.

The increasing investments by governments and industry participants in additive manufacturing are accelerating the development and adoption of 3D printers in the region.

The high growth potential of additive manufacturing is encouraging industry participants to enter into strategic partnerships to tap the market’s potentialities.