India to simultaneously grow hydrogen market and solar power

FCEVs offer faster fuelling, superior range and better cold-weather performance than BEVs

image for illustrative purpose

While both green hydrogen and solar energy contribute to renewable power, they also necessitate effective energy storage solutions. Battery storage systems, often associated with solar power, play a critical role in storing excess energy generated during sunny days for later use.

A new report highlights India’s potential to lead the fastest-growing market for hydrogen electrolysers by 2050, aiming to achieve net-zero emissions.

According to the report, India is projected to experience the highest growth rate in the expanding market for green hydrogen (H2) electrolysers in Asia, followed by China, Japan, and South Korea.

The report indicates a collective $180 billion opportunity for hydrogen electrolysers in key Asian markets by 2050. It was unveiled at an event held on April 12 in New Delhi.

BEV performance continues to lag conventional vehicles powered by fossil fuels in a number of aspects: cost, weight, range, charging time and performance in cold weather. Additionally, spent batteries often generate considerable waste because of limited recycling capacity. The supply chain associated with lithium ion battery production is also a concern.

Better battery technologies will certainly emerge in the years to come. However, improvements will likely be incremental because the required advances in chemistry, physics, and material science do not usually occur at the same rates as say, advances in information technology.

Fuel Cell Electric Vehicles (FCEVs) are becoming increasingly popular in the transportation sector, particularly in large-scale applications with high utilization rates such as busing, trucking, rail and maritime. FCEVs are powered by electric drive trains similar to BEVs, with the primary difference being FCEVs store energy primarily in tanks filled with hydrogen instead of large, heavy, battery packs. The much lighter weight associated with hydrogen fuel storage offers considerable advantages as vehicles, payloads and journeys are scaled up. Additionally, FCEVs offer much faster fuelling, superior range, and better cold-weather performance than BEVs. Many product developers also see considerable opportunities for future innovation that can improve performance and reduce costs.

Hydrogen has the potential to play a vital role in meeting the energy storage needs required to slash CO2 emissions. It is the most plentiful element in the universe and its capability as an effective energy carrier has been well-understood for decades

Hydrogen can be produced and used without toxic pollution or CO2 emissions. It burns clean when mixed with oxygen from the atmosphere and can be used as a source of heat or to power an internal combustion engine. Hydrogen can also be fed into a fuel-cell device that converts hydrogen’s chemical energy into electricity. In either case, the only emission produced is water vapour. When hydrogen fuel cells are used to power an electric motor, the system is more than twice as efficient as conventional internal combustion engines.

Hydrogen rarely exists in isolation but is amassed in enormous quantities in water, hydrocarbons, and biomass. Efficient extraction of hydrogen from these compounds is critical for wide scale deployment. Currently, about 95% of hydrogen is produced by splitting it from natural gas through a process called “steam-reforming.” Hydrogen produced in this manner is referred to as “gray” and is generally not considered an effective climate solution because it gives off CO2 as a by-product. However, it is possible to capture and sequester the CO2 to produce “blue” hydrogen at an additional cost of about 30%. The oil and gas sector, in particular Shell, BP, and Repsol, are interested in the blue hydrogen approach because it could help preserve the value of their natural gas assets.

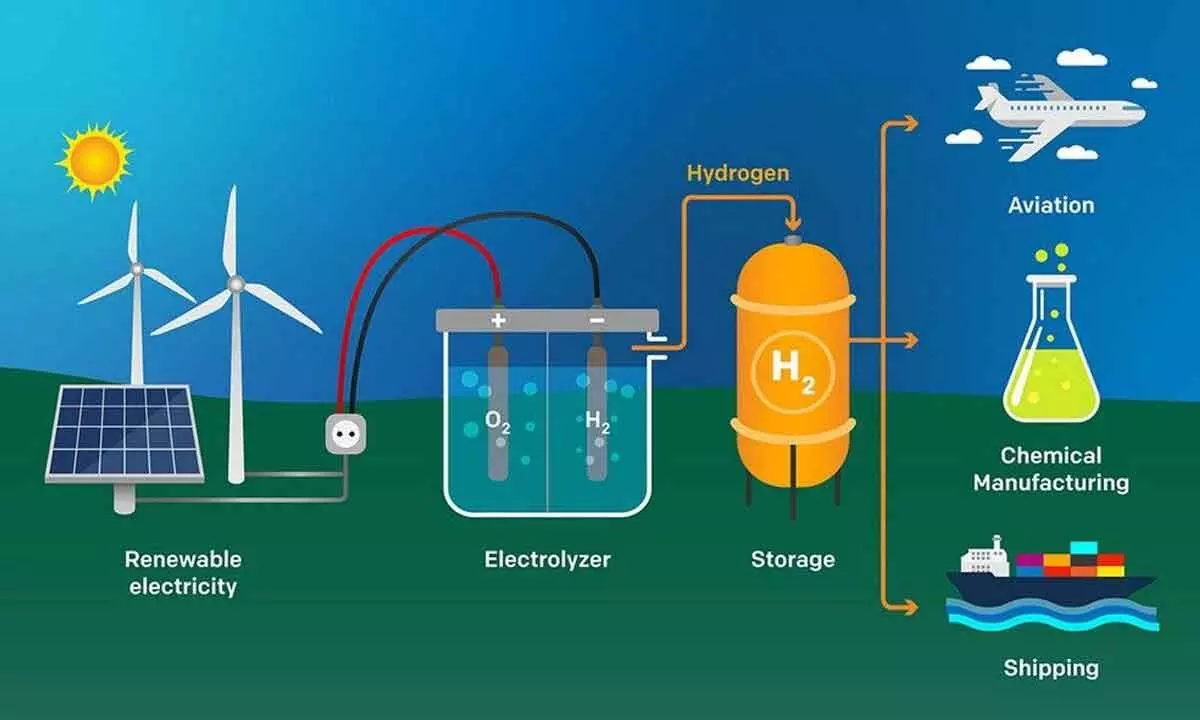

Hydrogen is the most equitable of all fuels because it can be produced wherever there is access to electricity and water using a process called electrolysis, where an electric current is used to split hydrogen from oxygen. If the electricity comes from renewable sources, the hydrogen fuel is considered to be renewable or “green” because it is produced without CO2 emissions.

Electrolysis is energy-intensive and has only recently been considered feasible as the cost of renewable power has declined and electrolysis technology has improved. Nuclear power can also provide the energy for electrolysis to split water without CO2 emissions. U.S. utilities Exelon, FirstEnergy, Xcel Energy, and Arizona Public Service have all committed to commencing small-scale hydrogen production at nuclear plants. For comparison purposes, a kg of hydrogen contains about the same amount of energy as a gallon of gasoline. However, a large portion of the higher cost can be offset by the fact that FCEV driven trains are more than twice as efficient and require less maintenance than internal combustion drive trains. Recent analyses performed by MIT and Wood Mackenzie predict that the cost of green hydrogen will decline 30% by 2030.